Passive vs. Active Closed-Loop Extraction

October 8, 2024

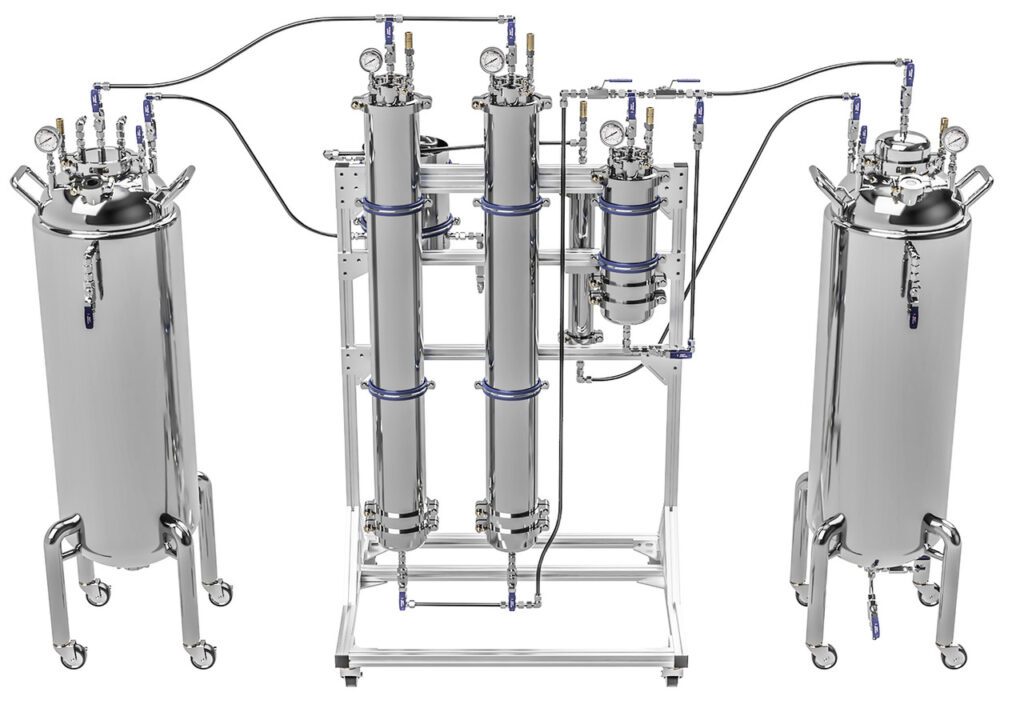

Closed-loop extraction involves using a solvent in a system that prevents contact with outside air, ensuring safety and efficiency. There are two main types: passive and active closed-loop extraction systems. Each has its own benefits and drawbacks, which can influence your choice based on your specific needs.

In a passive closed-loop extraction system, pressure is modulated, and the solvent is recovered by manipulating temperature within a closed environment. This method operates on the principle that gas seeks the lowest possible pressure. By strategically heating the gas in the collection tank and cooling the solvent recovery tank, the gas naturally transfers through the system. When the temperature in the recovery tank drops below the boiling point of the vaporized solvent, it recondenses into liquid form for recovery and reuse.

While this method is simpler and requires less maintenance, it has some downsides, such as increased solvent loss and generally slower extraction times.

Active closed-loop extraction systems also operate on similar principles but differ in their approach to solvent recovery. Instead of relying on natural processes, these systems use recovery pumps to accelerate solvent movement. The push-and-pull action of the pumps speeds up the recovery process and minimizes solvent loss.

Once vaporized solvent is directed into the recovery tank, a coil on the pump’s output port recondenses it back into liquid form. This method is generally faster, more cost-effective, and reduces the need for expensive chilling methods like dry ice, often used in passive systems.

However, active systems are more complex, which can be challenging for beginners. They require more maintenance, as the pumps need regular upkeep, and the initial investment is typically higher than that of passive systems.

When choosing between passive and active closed-loop extraction systems, consider your specific application needs, maintenance capacity, and budget. Each method has its strengths, making them suitable for different extraction goals.