Navigating Common Challenges in BHO Production

December 19, 2024

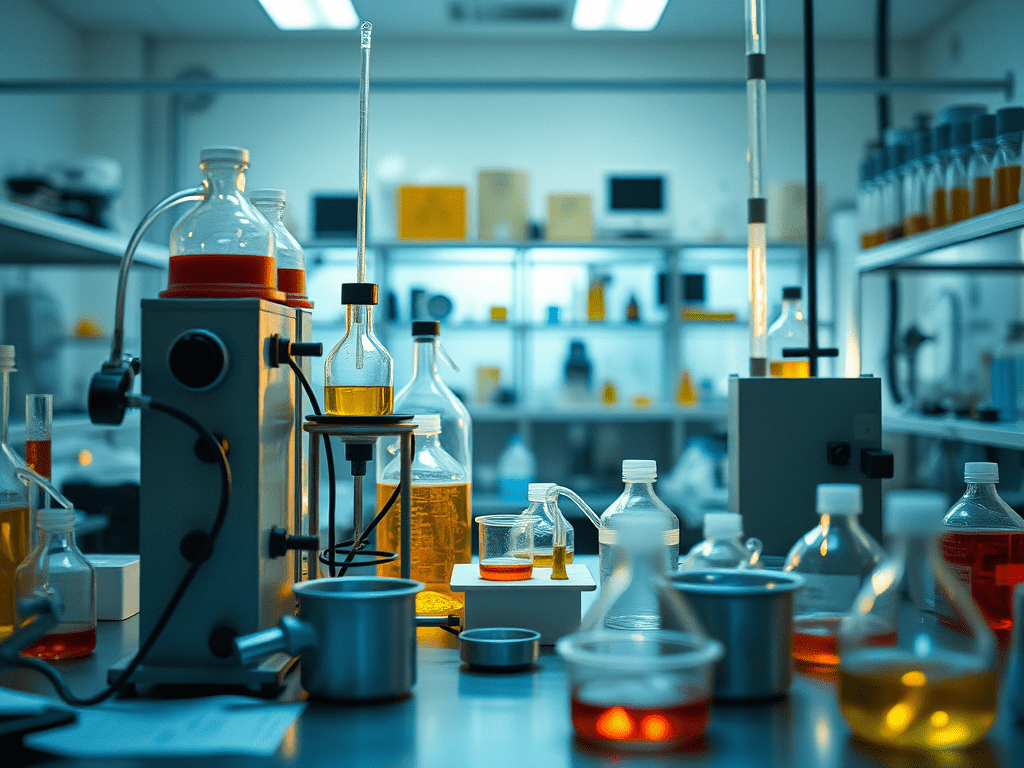

Navigating Common Challenges in BHO Production

Producing Butane Hash Oil (BHO) requires meticulous attention to detail. From handling nucleation to managing the presence of waxes and lipids, each step in the process can significantly influence the quality of your final product. Here’s a guide to understanding and overcoming common BHO production issues, ensuring the production of high-quality concentrates.

Nucleation often occurs with abrupt temperature changes during the extraction or storage phases, leading to the crystallization of THC, particularly at high concentrations. Similarly, the natural presence of waxes and lipids, while serving as protectors within the plant, can result in harsh and cloudy extracts when concentrated.

Managing Temperature and Quality:

Selecting Quality Plant Material: Using fresh, well-cured, or properly stored cannabis is crucial, as older or poorly stored materials tend to have higher lipid oxidation levels.

Insufficient purging can leave residual butane, affecting the purity and safety of the concentrate. Optimal purging involves precise temperature control and adequate vacuum settings to ensure complete solvent removal.

Enhancing Purge Processes:

Significant temperature fluctuations can lead to inconsistent quality and reduced yields. Implementing robust temperature control systems and monitoring tools can help maintain a stable environment conducive to high-quality production.

Strategies for Temperature Management:

Leaks in the extraction setup not only pose safety risks but also compromise the efficiency and compliance of your operation.

Maintaining Equipment Integrity:

Proper ventilation is critical to safely managing the volatile butane vapors produced during BHO extraction.

Optimizing Ventilation Systems:

Decarboxylation must be carefully controlled to activate THC without degrading valuable cannabinoids and terpenes.

Achieving Consistent Decarboxylation:

By understanding these common challenges and implementing strategic solutions, BHO producers can enhance their operational efficiency and product quality. Embracing these practices will help you navigate the complexities of BHO production and achieve success in the competitive cannabis extracts market.