What is Butane Extraction?

October 8, 2024

Butane extraction, or BHO extraction, uses butane as a solvent to extract THC, CBD, and other compounds from cannabis. This method differs from alcohol extraction, as it requires a closed-loop system to prevent off-gassing and reduce the risk of explosions. To ensure safety, BHO extraction is typically performed in a C1D1 lab, which is equipped with explosion-proof equipment and proper ventilation to prevent sparks from igniting flammable gases.

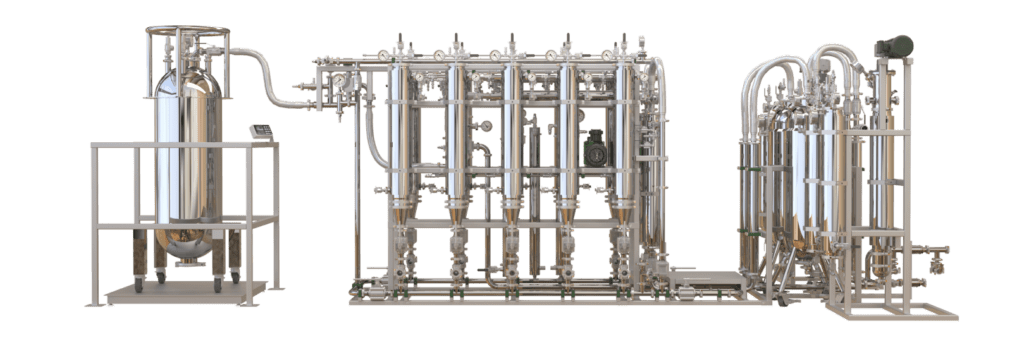

The BHO extraction process starts by packing stainless steel columns with cannabis plant material. Liquid butane is then passed through these columns at very low temperatures, which allows it to extract the desired compounds from the plant. The result is an extract that contains both butane and the targeted plant chemicals. Performing this step within a closed-loop system is essential to minimize the risk of explosion.

After extraction, purging is crucial to eliminate any excess solvent and ensure the safety and purity of the final product. A BHO purge oven is used for this purpose, providing stable temperature control to avoid burning off valuable compounds. The oven’s vacuum feature maintains consistent temperatures, even slightly above ambient levels, resulting in a product free of butane residue. These ovens are typically rated by their cubic feet of available space and come in various temperature and vacuum levels.

Safety First: Temperature monitoring is critical throughout the entire BHO extraction process to prevent hazards such as explosions. Using a closed-loop system and reliable equipment, like a BHO purge oven, minimizes the risk of accidents and ensures the safety of both the operator and the final product. As stated previously, this should be done within C1D1 and C1D2 zones respectively, to ensure safety throughout the entire process.