ISO Cleanrooms: The Ultimate Guide!

January 2, 2025

Understanding the Types of Cleanrooms and Their Applications

Cleanrooms play a vital role across industries, providing the controlled environments needed to ensure safety, precision, and product quality. From aerospace engineering to food manufacturing, cleanrooms are essential for processes where contamination could compromise results. Understanding the types of cleanrooms and their applications can help businesses select the right solution to meet their unique needs.

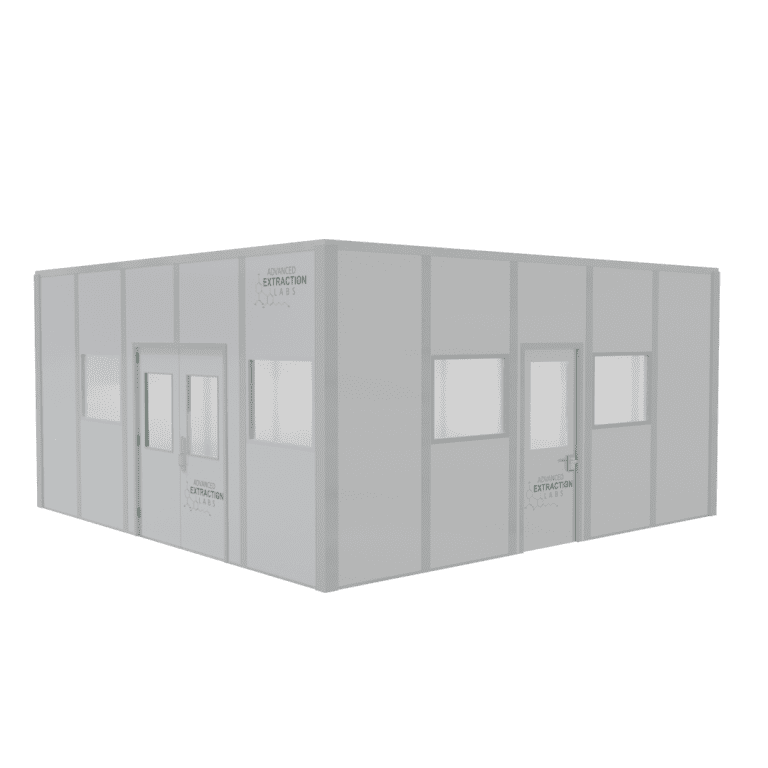

Hardwall cleanrooms are constructed with solid, durable panels made from materials like stainless steel, fiberglass-reinforced plastic, or aluminum. These cleanrooms are ideal for industries requiring stringent cleanliness standards, such as pharmaceuticals, biotechnology, and aerospace. Their robust construction provides superior contamination control and makes them easy to clean and maintain.

Softwall cleanrooms use lightweight vinyl curtains supported by a sturdy framework. They are a cost-effective solution for industries that require moderate contamination control but do not need the stringent standards of a hardwall cleanroom. These cleanrooms are quick to install and can be suspended from existing structures or set up as freestanding units.

Rigidwall cleanrooms combine the structural integrity of hardwall cleanrooms with the affordability and flexibility of softwall systems. They are constructed with modular, clear acrylic or polycarbonate panels that provide excellent visibility. Rigidwall cleanrooms are versatile, supporting a wide range of classifications from ISO Class 100 to ISO Class 100,000.

Seamless cleanrooms are built with flush, studless wall panels that eliminate exposed seams, ensuring maximum contamination control. These cleanrooms meet high cleanliness standards and are commonly used in industries requiring the strictest levels of precision and cleanliness.

Cleanrooms are not limited to one industry or purpose. They serve critical roles in many sectors, including:

Cleanrooms are classified based on the number and size of particles allowed per cubic meter of air. ISO standards provide a universal framework for measuring cleanliness levels:

Choosing the right cleanroom depends on your specific application and industry requirements. Factors like cleanliness standards, available space, and budget will influence your decision. Modular cleanrooms, in particular, offer flexibility and scalability, making them an excellent choice for businesses expecting growth or changes in their processes.

At Advanced Extraction Labs, we specialize in designing and installing cleanrooms tailored to meet the unique needs of your business. Whether you need a softwall cleanroom for a food processing plant or a seamless cleanroom for advanced research, we’re here to help you create the perfect environment for your application.

Contact us today to learn more about how we can help with your cleanroom project and take your operations to the next level.